Choosing between a sleeve bearing and a ball bearing cooling fan depends on what you need. If you want a fan that is quiet at first and costs less, a sleeve bearing is good. It works best in horizontal setups and with normal heat. If you want a fan to last longer and work well in any position, pick a ball bearing fan. Ball bearing fans also give steady performance. The table below shows the main differences:

| Sleeve Bearing | 20,000–40,000 | Quietest at first, but noise rises quickly | Horizontal only | Lower |

| Ball Bearing | 40,000–80,000 | Louder at first, but noise stays stable | Any position | Higher |

When you buy a dc cooling fan, think about these things. Coofan has choices to help you find the right fan for your needs.

Key Takeaways

Pick sleeve bearing fans if you want quiet and cheap fans. They work best in flat and cool places. Noise is not a big problem as time goes on. – Choose ball bearing fans if you need them to last longer. They make steady noise and can be put in many ways. They are good for hot or hard places. – Ball bearing fans cost more at first but last longer. They also need less fixing, so you save money later. – Only put sleeve bearing fans flat, or they will wear out faster. Ball bearing fans can be put in any way and still work well. – Pick your fan by thinking about noise, how long it lasts, price, and how you will set it up. This helps you get the best cooling.

Comparison

Sleeve Bearing vs Ball Bearing

When you look at cooling fans, you should see how each bearing works in real life. Sleeve bearing fans use sliding friction. The fan shaft slides inside a sleeve with oil. This makes the fan quiet at first and keeps the price low. Ball bearing fans use rolling friction. Small steel balls help the shaft spin. This makes the fan last longer and work in any position.

Tip: If you want to put your fan up and down or use it in hot places, ball bearing fans do better than sleeve bearing fans.

Here is a technical chart to show the main differences:

Technical Parameter | Sleeve Bearing | Ball Bearing |

|---|---|---|

Friction Mechanism | Sliding friction | Rolling friction |

Mean Time Between Failures | 20,000–40,000 hours | 50,000–100,000 hours |

Acoustic Profile (dBA) | 25–35 | 30–45 (at high speed) |

Maintenance Requirement | Periodic relubrication | Sealed-for-life |

Relative Cost Index | Base cost (1.0) | 1.5–2.0 times higher |

Operating Temperature Range | -10°C to +70°C | -20°C to +120°C |

Ingress Protection Rating | IP20 (open) | IP54 (sealed) |

Speed Capacity (RPM) | Up to 6,000 | Up to 12,000 |

Mounting Orientation Sensitivity | Performs best vertically | Orientation-insensitive |

Lubrication Characteristics | Fixed lubricant amount prone to evaporation | Thicker, additive-rich sealed lubricants |

Point of Contact | Line contact causing more friction | Point contact causing less friction |

Key Differences

You need to pick the right fan for your job. Here are the biggest differences between sleeve bearing and ball bearing fans:

Lifespan: Ball bearing fans last much longer. They can run for 50,000 to 100,000 hours, even in hard places. Sleeve bearing fans last 20,000 to 40,000 hours. If it gets hotter than 70°C, sleeve bearings can break faster.

Noise: Sleeve bearing fans are quieter when new, mostly at slow speeds. They get louder as the oil dries out. Ball bearing fans might be a bit louder at first, but their sound stays the same for years. New ball bearing fans can be quiet, even when spinning fast.

Cost: Sleeve bearing fans are cheaper to buy. Ball bearing fans cost more at first, but you save money later because you do not need to replace them as often.

Orientation: Sleeve bearing fans work best when flat. Ball bearing fans work in any way you put them, so you have more choices.

Application: If you want a quiet, cheap fan and will use it flat, pick a sleeve bearing fan. For strong, upright, or hot jobs, ball bearing fans are better.

Note: Experts say the old ‘Oilite’ sleeve bearing uses oil-filled brass to last longer, but it still wears out faster than ball bearings, especially if you use it a lot. New types like Fluid Dynamic Bearings try to fix these problems, but ball bearings are still best for tough jobs.

Here is a quick list to help you choose:

Pick a sleeve bearing fan for quiet, cheap, flat setups.

Choose a ball bearing fan for long life, any position, and hot places.

Always pick your fan based on what you need, like noise, price, and how you will use it.

Brands like Ebmpapst and NMB use ball bearings for big jobs, while other brands try to balance price and noise for home or office.

Check your fan often to make sure it still cools well.

Lifespan

Durability

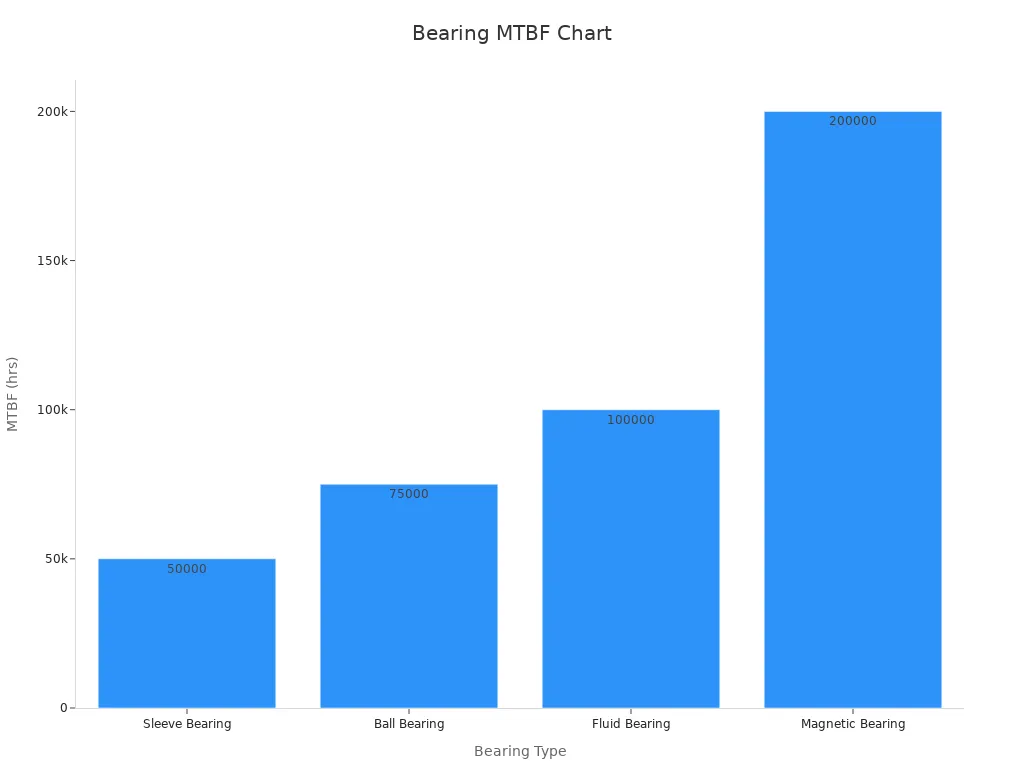

You want your cooling fan to last as long as possible. Ball bearing fans give you the best durability. They can run for up to 8 years without stopping. Most ball bearing fans reach an L10 life expectancy of 60,000 to 70,000 hours. Their MTBF (Mean Time Before Failure) often falls between 250,000 and 300,000 hours. These numbers show that ball bearing fans work well in tough conditions and keep running for years.

Sleeve bearing fans do not last as long. You can expect about 3 to 4 years of continuous use. Their L10 life is about half that of ball bearing fans. MTBF also drops to about half. High heat or mounting the fan in a vertical position can shorten the life even more. If you need a fan for a short project or a low-stress job, a sleeve bearing fan can work. For long-term use, ball bearing fans give you more value.

Here is a table to help you compare:

Metric | Ball Bearing Fans | Sleeve Bearing Fans |

|---|---|---|

Operational lifespan (90% functional) | 8 years of continuous use | 3-4 years of continuous use |

L10 Life Expectancy | 60,000 – 70,000 hours | ~30,000 – 35,000 hours |

MTBF | 250,000 – 300,000 hours | ~125,000 – 150,000 hours |

Temperature Range | -70°C to +80°C | More limited |

🛠️ Tip: Choose a ball bearing fan if you need a cooling solution that will last for many years, even in harsh environments.

Maintenance

You want a fan that needs little care. Ball bearing fans come sealed from the factory. You do not need to add oil or check them often. They keep working with almost no help from you. This makes them a good choice for places that are hard to reach or where you cannot stop for repairs.

Sleeve bearing fans need more attention. The oil inside can dry out over time. When this happens, the fan gets noisy and may stop working. You might need to replace the fan sooner or add oil if possible. If you use a sleeve bearing fan, check it often to make sure it still runs smoothly.

Noise

Low-Speed Operation

You want a quiet fan, especially when it runs at low speed. The type of bearing inside the fan makes a big difference. Sleeve bearing fans use sliding friction. This means the shaft rubs against the sleeve, which creates more noise, even at low speeds. Over time, the oil inside a sleeve bearing can dry out. When this happens, the fan gets louder.

Ball bearing fans use rolling friction. Small metal balls help the shaft spin smoothly. This design reduces friction and keeps noise levels lower, even when the fan spins slowly. You get a more stable and quiet performance.

📝 Note: Ball bearing fans usually stay quieter than sleeve bearing fans, especially as they age.

Long-Term Noise

You want your fan to stay quiet for years. Sleeve bearing fans start out quiet, but their noise level rises quickly. The oil inside evaporates or dries up, which increases friction. As a result, the fan gets louder and may even start to rattle.

Ball bearing fans keep their noise level steady over time. The rolling balls inside do not wear out as fast. You get a fan that sounds almost the same after years of use. This makes ball bearing fans a better choice for places where you need long-term quiet operation.

If you need a fan for a quiet office, a server room, or any place where noise matters, ball bearing fans give you the best long-term performance. You will notice less change in sound, even after thousands of hours of use.

Cost

Upfront Price

When you look for cooling fans, price is important. Sleeve bearing fans usually cost less than ball bearing fans. They use simple parts and are easy to make. This helps keep the price low. If you need many fans or want to save money, sleeve bearing fans are a good choice.

Ball bearing fans cost more to buy. They have more parts and need careful assembly. You pay more at first, but they are made for tough jobs. If you need a fan for an important system, the extra cost is worth it.

Here is a quick price comparison:

Bearing Type | Typical Price Range (USD) |

|---|---|

Sleeve Bearing | $1 – $4 |

Ball Bearing | $2 – $15 |

💡 Tip: If you only need a fan for a short project or a cool place, a sleeve bearing fan can help you save money at the start.

Value Over Time

You should think about the total cost, not just the price tag. Ball bearing fans cost more at first, but they save money later. They last longer, so you do not replace them as much. You also spend less time and money fixing them.

Sleeve bearing fans are cheaper to buy but do not last as long, especially if used flat or in hot places.

Ball bearing fans cost more at first but last longer and work in any position.

Ball bearing fans need less fixing and fewer replacements over time.

For short jobs or cool places, sleeve bearing fans can be a good deal.

For long jobs, hot places, or if you need the fan to last, ball bearing fans are better for saving money over time.

🛠️ Note: If you want to stop replacing fans often, buying a ball bearing fan is smart. For long projects, paying more at first can save you money later.

Orientation

Mounting Flexibility

You need to think about how you will mount your cooling fan. The way you install the fan can affect its performance and lifespan. Ball bearing fans give you the most flexibility. You can mount them in any position—horizontal, vertical, or even upside down. The design of ball bearings keeps the shaft stable no matter how you place the fan. This makes ball bearing fans a top choice for complex systems, server racks, or tight spaces.

Sleeve bearing fans work best when you mount them horizontally. If you install a sleeve bearing fan vertically or at an angle, the oil inside can move away from the shaft. This causes more friction and faster wear. You may notice more noise or even early failure if you do not follow the correct mounting direction.

💡 Tip: Always check the mounting instructions before you install a sleeve bearing fan. If you need to mount your fan in a non-horizontal position, choose a ball bearing fan for better reliability.

Here is a quick comparison:

Bearing Type | Mounting Positions Supported |

|---|---|

Sleeve Bearing | Horizontal only |

Ball Bearing | Any position |

Performance by Position

The position of your fan affects how well it works over time. Ball bearing fans keep their performance steady, no matter how you mount them. You get the same airflow and noise level in any direction. This makes them ideal for industrial machines, power supplies, and places where you cannot control the fan’s orientation.

Sleeve bearing fans lose performance if you mount them vertically. The oil inside can shift, leading to dry spots and more friction. You may hear more noise or see the fan slow down. Over time, this can cause the fan to fail sooner than expected.

For best results, use sleeve bearing fans only in horizontal setups.

Use ball bearing fans if you need to mount the fan in any direction or if the fan will move during use.

🛠️ Note: If you want a fan that works well in any position, ball bearing fans give you the best performance and longest life.

Applications

Sleeve Bearing Uses

Pick a sleeve bearing fan if you want quiet and cheap fans. These fans work well in home electronics and computers. They are also good for entertainment systems. You get the best value when you use them flat and in cool rooms. Many people use them in house fans and small machines. They are also used in things that do not run all day.

They are quieter at slow speeds, so they are good for bedrooms or offices.

They have low starting power, so they can turn on and off a lot.

They are best for projects where you want to save money and do not need the fan to last a long time.

They can be used standing up if the job is easy and short.

If you need a dc cooling fan for your home, a sleeve bearing fan from coofan can help you save money and keep things quiet.

Ball Bearing Uses

Pick a ball bearing fan for hard jobs. These fans last longer and work in any way you put them. You can use them in big machines and server racks. They are also good for power supplies. Ball bearing fans work well in hot and dusty places.

They work well in any direction, even upside down or sideways.

They can last more than 50,000 hours, even in hot rooms.

They are great for factories, data centers, and fast machines that run all the time.

They can handle heat, dust, and shaking.

Application Type | Sleeve Bearing Fan | Ball Bearing Fan |

|---|---|---|

Home/Office | ✔️ Best fit | Possible, but overkill |

Industrial/Server Room | Not recommended | ✔️ Best fit |

High Temperature | Not recommended | ✔️ Best fit |

Flexible Mounting | Not recommended | ✔️ Best fit |

Cost-Sensitive | ✔️ Best fit | Higher upfront cost |

If you need a fan for tough places, a dc cooling fan with ball bearings from coofan gives you the strength and choices you need.

Pick a cooling fan that fits what you need. Ball bearing fans last longer and can be put in any position. They also keep the same noise level over time. Sleeve bearing fans are quieter and cost less if you use them flat. Think about how long you want the fan to last, how loud it can be, how much you want to spend, and how you will place it. Coofan has good dc cooling fans for all kinds of uses. Make sure to look at your choices before you buy.

FAQ

What is the main difference between sleeve bearing and ball bearing fans?

You will find that sleeve bearing fans use sliding friction, while ball bearing fans use rolling friction. This difference affects lifespan, noise, and mounting options. Ball bearing fans last longer and work in any position.

Can you use a sleeve bearing fan vertically?

You should avoid mounting sleeve bearing fans vertically. The oil inside can move away from the shaft, causing faster wear and more noise. For vertical or flexible mounting, choose a ball bearing fan.

Which fan type is quieter over time?

Ball bearing fans maintain a steady noise level for years. Sleeve bearing fans start out quieter, but they get louder as the oil dries out. For long-term quiet operation, ball bearing fans work best.

Are ball bearing fans worth the higher price?

You pay more upfront for ball bearing fans, but you save money over time. They last longer, need less maintenance, and work in tough conditions. For critical or long-term use, ball bearing fans offer better valu